What is Torero

TORrefying wood with Ethanol as a Renewable Output: large-scale demonstration

Torero will demonstrate a cost-, resource-, and energy-efficient technology concept for producing bioethanol from a wood

waste feedstock, fully integrated in a large-scale, industrially functional steel mill:

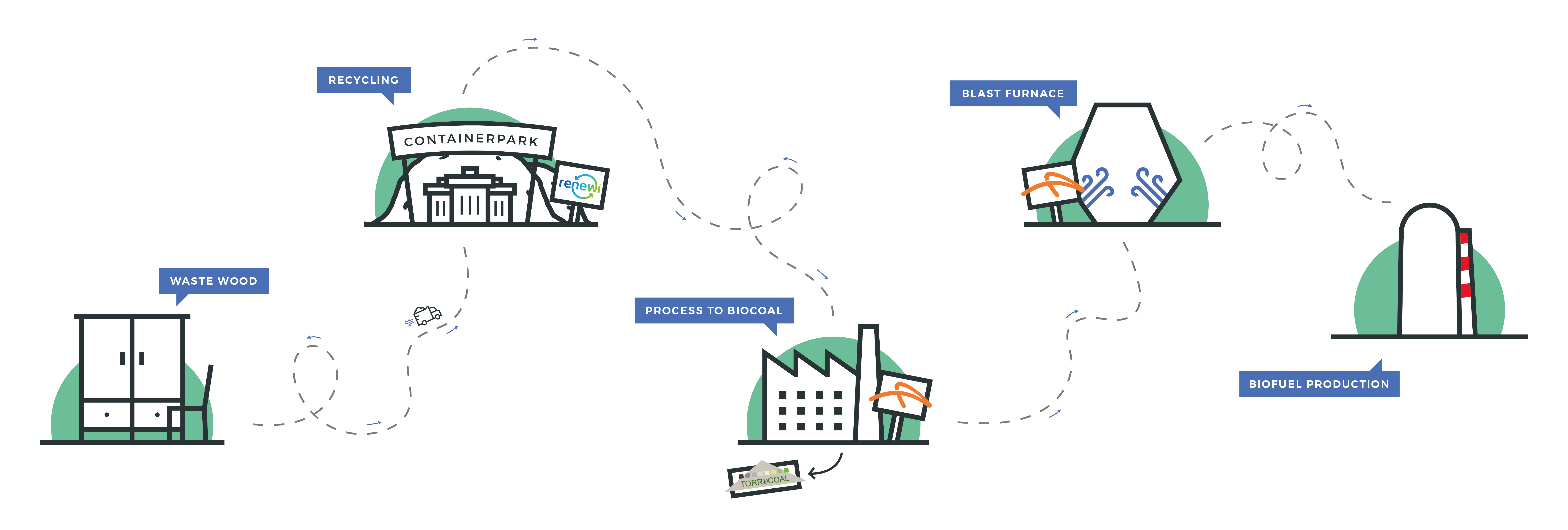

- Wood waste is converted to biocoal by torrefaction

- Biocoal replaces fossil powdered coal in a steel mill blast furnace

- Carbon monoxide in blast furnace exhaust fumes is microbially fermented to bioethanol

- Material and energy loops of the process are closed to a very large degree

Every steel mill that implements this concept will be able to produce at least 80 million litres of bioethanol per year. This project creates a value chain for wood waste, which currently has no attractive applications. The technology concept is open ended: in the future, stakeholders may replicate the concept with other feedstocks and for producing other types of fuels.

The business case of the Torero project will produce a competitive process for non-food feedstock bioethanol production.

Compared with the current first generation production based cellulosic bio-ethanol solution the Torero innovation the OPEX of Torero is 1/3 lower with a same CAPEX. This will allow scale up of torrefaction technology when successfully demonstrated. Most importantly, together with sister project Steelanol, Torero will be the only H2020 project to demonstrate a biofuel production process that is integrated in an existing, fully functional large-scale industrial facility. All other H2020 solutions will need to be newly built if they ever reach full industrial scale. Torero is an add-on technology that can be used to upgrade existing facilities of the steel sector, an industry that is actively scouting for technological solutions to make its production processes more sustainable. The consortium consists of full value chain, industry ArcelorMittal and Renewi , two expert research organisations Joanneum Research and Chalmers Technical University and torrefaction technology supplier TorrCoal.

latest news about torero

the process

Transforming waste wood to biofuel

The Torero project will provide a new use for Type B wood waste for production of biomass feedstock for renewable bioethanol for use in the transport sector. This will be done by a new implementation of torrefaction technology in a biomass feedstock production process that will be developed and proven in this project. The torrefaction technology, developed and to be adapted by consortium partner TorrCoal, will produce torrefied wood as a biomass which will replace a significant portion of fossil fuel within the blast furnace and reduce the GHG emissions. The blast furnace is (besides the s teel production) used as a gasification unit and will lead through existing fermentation technology to the production of bioethanol.

The torrefaction technology process implementation in Torero will be done without need to rebuild the BAT (Best Available Technologies) steel and sinter plant. This will supply the end-user transport sector with a high grade biofuel, bioethanol, that does not compete in any way with food crops or land for food crops. This technology therefore provides the unique opportunity to recycle the carbon from industrial exhaust rich gases that would otherwise be emitted into the atmosphere.

Europa

With the support of the European commision

Via the Horizon 2020 program a subsidy of 11.5 million euro has been granted to the construction of the new production facility and the startup phase. The project was named ‘Torero’. The objectives of Torero are fully in line with the H2020-LCE-19-2016-2017 challenges.

TORERO has received funding from the European Union’s Horizon 2020 - Research and Innovation Framework Programme (H2020-EU.3.3.3. - Alternative fuels and mobile energy sources). Project ID: 745810.